Air conditioning system winter checks

It’s an unfortunate fact that air conditioning (AC) systems are often disregarded as the weather gets colder. However, as well as for the comfort of the occupants, a fully functioning AC system is an important safety feature, because good visibility is a necessity, whatever the time of year.

“As a result, alongside other winter checks, technicians should ensure the AC system is in good shape and all the joints in the loop are tight because, despite there being no need to cool the cabin in winter, the system can very effectively demist the windows, which is vital for general road safety,” says Marketing Manager, Jan Zieleskiewicz. “In fact, the system should be kept operational at all times, even if it may shut off automatically because of lower outside temperatures (typically, the compressor won't start below temperatures of three degrees Celsius), as keeping it in working order is essential.

Lubrication

“The proper lubrication of AC components and their internal parts, such as the inner moving parts in the compressor for example, is critically important for the overall lifespan of the entire system. However, this can only occur with the presence and correct circulation of the refrigerant in the system, which facilitates the movement of the lubricant. Therefore, for systems with a compressor with an electromagnetic clutch, it is advisable to use the AC all the time, or at the very least, it should be activated regularly.

“Besides the task of lubricating the compressor's mechanical parts, the flow of the refrigerant and oil mixture is essential for sealing the AC loop effectively, such as sealing the compressor shaft, for example. The longer the system is inactive, the more likely the seal will dry, which can lead to severe leakage from the compressor shaft and will provoke other consequential failures.

“In systems circulated by clutchless compressors – those with variable displacement and control of MCV or ECV valves – constant lubrication is also of critical importance. The majority of these compressors run all the time, so serious system undercharge or refrigerant leaks, will impair the circulation of the lubricant, which in the worst-case scenario, may lead to compressor burnout and seizure, with a high probability of severe consequential failures, such as a broken/torn auxiliary drive belt.

Joint tightness

“Refrigerant leaks are the primary culprit in system failures. Although minor losses are difficult to spot, particularly in the colder seasons when the system is not required to perform at its highest level, as previously mentioned, severe losses will lead to critical failures. It is, therefore, good to inspect the system regularly. Oily stains on the surfaces of the AC loop can highlight leakages, so whenever a vehicle is in the workshop for general service or repair, technicians should examine the loop couplings, compressor housing and condenser surface. Oil residues attract dust, which makes them easy to spot, but suspicions of a severe leakage will require a complete AC system service, whatever the season.

“Refrigerant losses can also come as the result of leaky service ports as the mechanical part of the Schrader valves is often vulnerable to leaks after long periods of inactivity or if the system is undercharged. The cost of changing a port valve is minimal, but can save the system from more severe failures, so is a worthwhile precaution.

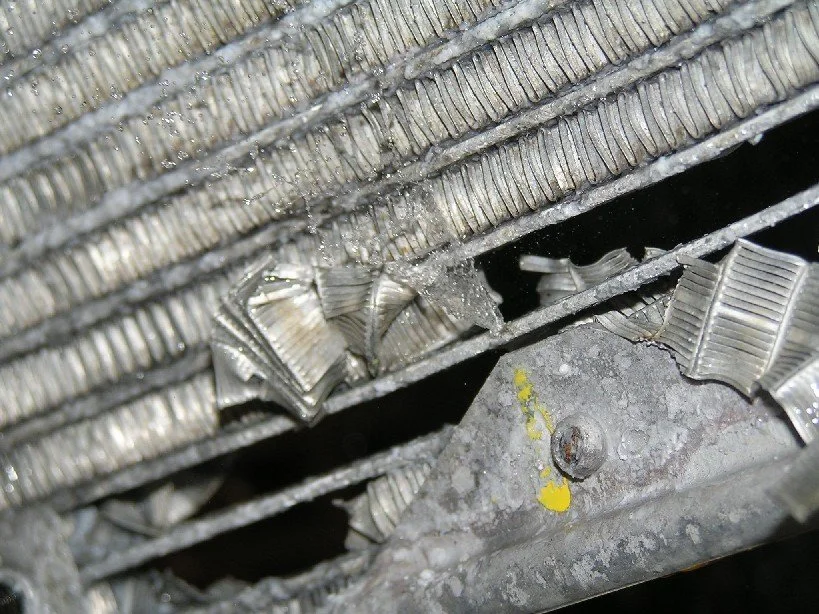

The condenser

“The condenser is one of the most vulnerable parts of the AC loop and yet, the most critical for the correct operation of the system. It can often be quite exposed and therefore susceptible to leaks due to humidity, dust and salt from the road. Furthermore, even surface soiling or deterioration will impact its function, leading to the possibility of severe system failures, such as overpressure or compressor overload.

“A thorough visual inspection is therefore highly recommended whenever a vehicle enters the workshop, and when a new condenser needs to be fitted, it is advisable to choose a high quality replacement part with a corrosion-protective coating, such as a Nissens condenser, which comes with anti-corrosion protection as standard.

Airflow

“The airflow around the system is another critical aspect for the correct function of the vehicle’s AC and this requires inspection, whatever the season. As already mentioned, the condenser is naturally the first part to examine and besides its surface, the proper operation of the AC fan and elimination of any dust and soiling from its housing are important things to check.

“However, when it’s colder, another area of the AC system that requires attention is the cabin air intake and filtration, as this has a tremendous influence on the system’s performance. Whenever these are impaired, it can cause severe problems, which it is also possible for the occupants to notice when the heater is on. Clogged air filters or ducts, or impaired function of the cabin blower, may also expose the AC compressor to problematic conditions, as a lack of airflow affects the refrigerant's state change in the evaporator.

“Another problem area is clogged moisture outflow ducts because, as condensation is a natural effect of the high-temperature differences around the evaporator, it must find an easy way out of the vehicle and this is made possible by outflow ducts. If, however, their function is impaired, by some sort of restriction, for example, the condensation will accumulate within the compartment, and this moisture will quickly cause the housing’s padding and foam to rot, causing odours, bacteria and mould to formulate.

“Therefore, regular inspection of the housing and its ducts, and replacement of the cabin air filter is highly recommended, even in colder seasons. The airflow within them can quickly be affected by leaves and plant debris, which is naturally more common in the autumn season. The cabin blower inside the housing should also be checked to make sure it starts and works properly, to ensure the airflow in the system is circulated correctly.”

For the past nine decades, Nissens has been dedicated to delivering a comprehensive thermal management product range and its specialist know-how, manufacturing experience and deep insight of thermal systems, mean it has the flexibility to meet the needs of existing and emerging markets, to supply a wide range of high-quality replacement parts across multiple sectors.

For more information regarding the Nissens aftermarket range, visit: www.nissens.com