Nissens Automotive Heater and Cabin Blower Update

The arrival of very cold weather brings a surge of business into the independent service and repair sector

The arrival of very cold weather brings a surge of business into the independent service and repair sector, as the cold conditions can have a significant impact on many of a vehicle’s components, including the heating, ventilation and air conditioning (HVAC) system, which has to work particularly hard to keep the occupants safe and comfortable.

Although the major components within the HVAC system do the primary work, the heater and cabin blower both have vital roles as they respectively heat the cold air from outside and circulate it effectively around the cabin. It is therefore, wise to include each item during an annual check and, if either need replacement, use only premium quality aftermarket products.

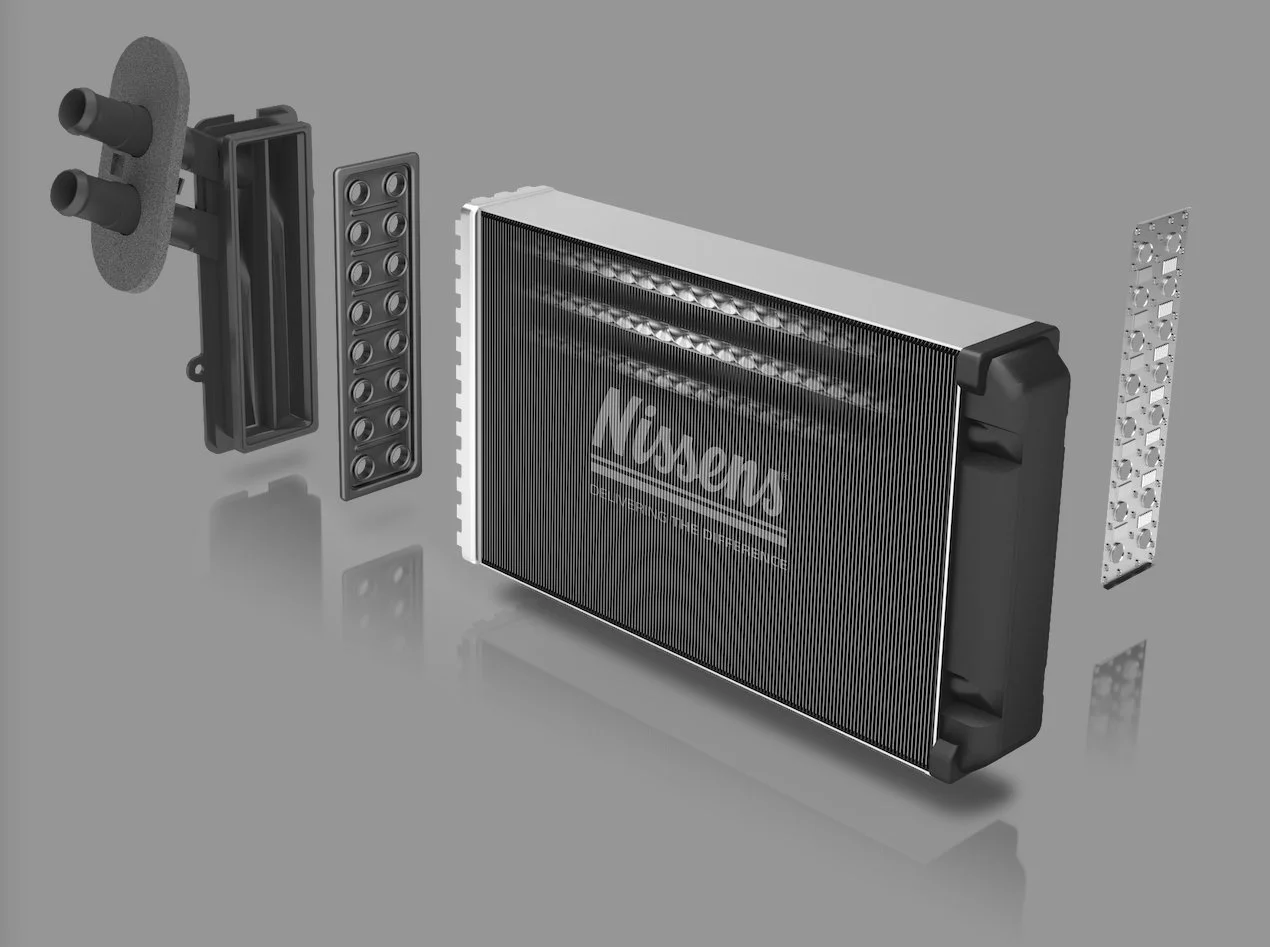

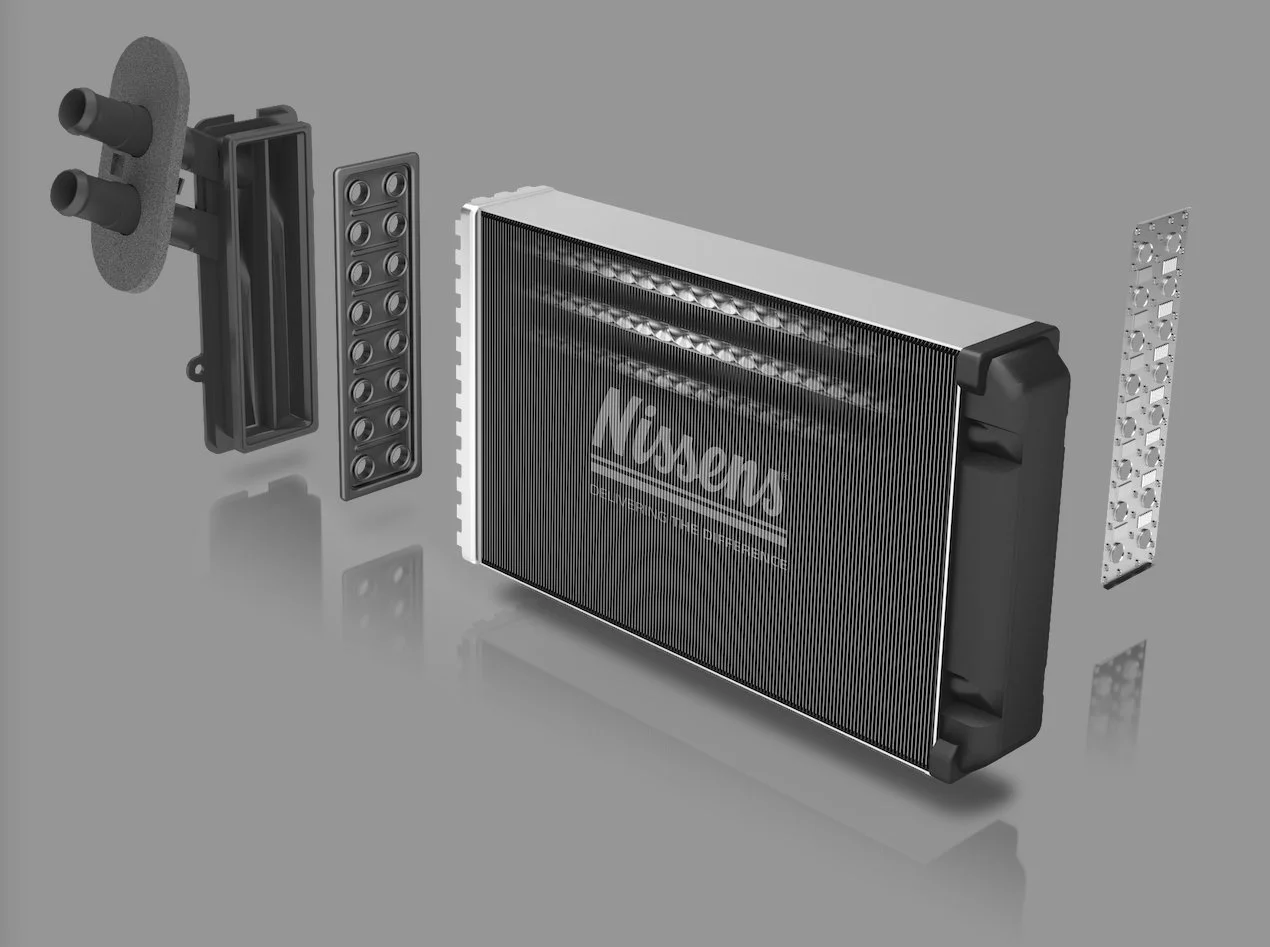

Nissens Automotive (Nissens) is a thermal management expert and its replacement components are designed and manufactured in accordance with its strict Genuine Nissens Quality standards, to ensure that they operate to the same performance levels as the original equipment (OE) part, to provide independents with a premium quality solution they can depend on. From an installer’s perspective, this also means that they are also straightforward to fit and that, whenever they are required, additional components, such as nuts, bolts, clips etc, are supplied within the Nissens box.

As a thermal management specialist that is solely focused on providing aftermarket solutions, Nissens is particularly aware of the elements within a heater and a blower that are prone to wear or fail, and is therefore able to ensure these are areas that its components benefit from extra attention.

As a result its heaters include high performance core tubes with turbulators, the core fins have louvres to ensure efficient heat exchange properties and they are fitted with EPDM gaskets to resist thermal stress. When it comes to its blowers, they incorporate a high quality electric motor armature, durable carbon brushes with power surge protection and robust control units and electrical resistors.

In terms of range, 380 Nissens heaters cover 1,100 OE references and 82% of the European car parc, and include popular applications such as Ford EcoSport, Hyundai Tucson, Toyota Aygo, Vauxhall Corsa and Mokka, as well as VW Passat and Polo. In terms of blowers, 360 part numbers cover 1,190 OE references and 75% of the European car parc, with BMW X1, Citroën Berlingo, Ford Focus, Mercedes Vito, Peugeot 3008 and Toyota Rav4 among the popular applications.

Nissens replacement parts are available from motor factors across the country, but to learn more, visit: www.nissens.com

PowerEdge winter wiper tips

PowerEdge provides some useful tips to reduce winter driving anxiety and keep drivers safe on the roads

As winter draws in, PowerEdge, the competitively priced replacement parts offering supported by DENSO Aftermarket, provides some useful tips to reduce winter driving anxiety and keep drivers safe on the roads during the worst of the cold weather

With winter officially here, it’s more important than ever for drivers to assess and potentially replace the wiper blades of their vehicles, as they’re one of its most safety critical components. This is particularly important because the ultra-violet rays from the sun during the long days of summer can cause damage to the rubber wiping element of the blade, so these will need to be checked to ensure they are in good condition.

Gently clean the rubber blade edge with a damp cloth or sponge to remove any dirt or residue. Check along its length for any imperfections in the rubber, particularly at either end that it has not split. Ensure that the rubber element returns to a central position and is not flipped over and set in one direction. If the blade fails any of these checks, it should be replaced.

Using the washer spray or a mister bottle to spray the glass, operate the wipers and check that there are no uncleared areas, water smears or multiple streaks that impair vision. Any light misting remaining after the wipe should disappear quickly. Naturally, blades that leave streaks or smears should be replaced.

It is also important to make sure the blade is securely fixed to the wiper arm. The blade should rotate freely, parallel with the wiper arm, to allow it to flex over the screen, but there should be no wobbling or movement perpendicular to the arm. This movement can be a sign of wear from the blades flipping over and could eventually cause the blades to come apart during use. Naturally, if the blade shows excessive movement, replace it immediately.

In addition to the wipers themselves, the surface they run over needs to be checked, so ensure the windscreen is thoroughly cleaned using warm water or specialist glass cleaning fluid. In particular pay attention to the areas at the top and bottom of the wiping area, as dirt and debris collect there. Also check the glass for any cracks or chips, as these are a safety hazard in their own right, but can also damage the wiper blade rubber.

Despite these best practice tips, as a wiper blade naturally wears, the time will inevitably come when the vehicle’s wiper blades will need replacing, which is where PowerEdge steps in with a new range of competitively priced products, backed by the class leading sales, service and logistical support of DENSO Aftermarket, one of Europe’s premium replacement parts suppliers. PowerEdge wiper blades are available in two types – flat and conventional (lengths from 350-700mm).

Developed in accordance with demanding design standards and component usage, and therefore able to withstand the demands of varied conditions, the products are meticulously crafted to deliver unmatched durability, reliability and performance. As a result, PowerEdge is the perfect option for drivers that are looking for durable and cost effective components that meet the requirements of the growing need for mid-price, high quality product solutions.

To ensure the correct specification replacement blade is identified and the ideal option selected, visit the PowerEdge E-catalogue.

To see how easy it is to install PowerEdge wiper blade, follow the PowerEdge video instructions.

For more information regarding PowerEdge products, please visit www.poweredgeproducts.eu or speak to a DENSO Aftermarket distributor.

DENSO Aftermarket’s winter wiper tips

As winter fast approaches, DENSO Aftermarket provides drivers with some useful tips to reduce the anxiety of winter driving

As winter fast approaches, DENSO Aftermarket provides drivers with some useful tips to reduce the anxiety of winter driving, prolong the life of their wiper blades and, most importantly, stay safe when the weather is cold and icy

Most drivers pay little or no attention to the wiper blades on their vehicle, but these underappreciated components are vital to their health and wellbeing, as being able to have a good view of the road ahead is vital whatever the time of year and whatever the weather conditions.

Although there are best practice tips that are relevant to the drier summer months, such as checking their general condition to make sure they are smooth and flexible with no cracks or notches, and cleaning any dust and deposits off the rubber wiping edge of the blades with water and a little detergent, as well as removing tree sap or insect residue from the windscreen with a purpose made cleaning solution, it’s when the weather is colder that the greatest attention should be given.

Despite the fact that drivers might be tempted to simply turn on the wipers when they are faced with ice on the windscreen after an overnight frost, this is really the worst thing to do because the rubber edge of the blade could actually be frozen to the screen, which can cause it to tear, but even if that doesn’t happen there are few things worse for this rubber edge than scraping across an icy windscreen, because frost is surprisingly abrasive! In addition, the strain on the wiper arms, joints and motor could result in even bigger problems and an unwelcome repair bill.

So, a really useful tip when the weather turns chilly is to lift the blades away from the glass when the car is parked. Most wiper arms are designed to be moved and stay in this position because it aides the removal and installation process, when worn blades are replaced, but where this is not the case, sliding a plastic bag over the blade before resting it back on the screen, will also prevent them from freezing to the glass.

While using hot water from a kettle may appear to be the quick and easy way to de-ice the screen, it can cause real damage, as the extreme and sudden change in temperature can cause the glass to crack or even shatter.

So, if using the wipers and pouring on hot water are the wrong way to de-ice that windscreen, what’s the right way? Well, there are plenty of specific accessories, like scrapers and snow brushes, and de-icing products such as liquids/sprays that are readily available and will do the job quickly and effectively, but don’t wait until the weather has closed in and the icy mornings have begun before stocking them!

While these are good ways to de-ice your vehicle, there are actually some simple tricks to stop your windscreen from freezing to begin with, such as using a windscreen cover that will stick to the corners of the windscreen or be held in place by clamping in the doorframes. Failing that, an old blanket or even cardboard will work, just as long as it’s tightly fitted. Finally, if one is available, another is to use a garage, as this will also prevent snow building up on the vehicle should there be a fall.

Despite these best practice tips, as a wiper blade naturally wears with use, the time will inevitably come when the vehicle’s wiper blades will need replacing. However, as a safety crucial component, DENSO wiper blades are meticulously manufactured and tested to ensure they meet precise standards of fit and performance.

The DENSO Hybrid range is a great choice whatever the weather, but, in addition to its modern and stylish appearance, and excellent high speed wiping performance, it provides winter benefits too. Designed to perform in extreme weather conditions, the stiff, integrated structure means these hybrid blades can perform better for longer. As well as holding to the surface of the windscreen more effectively, the advanced design makes them highly resistant to the elements, particularly frost and snow, as the plastic body helps prevent icing, while the hinge mechanism maintains the blade’s flexibility, even when the frost is severe.

With a proven original equipment heritage and a history of pioneering new designs, DENSO wiper blades should be the first choice replacement option, as they are thoroughly tried and tested, so their quality and performance make them a solution that both motorists and aftermarket professionals can rely on.

Further details of the DENSO Aftermarket wiper blades are available in DENSO E-catalogue.

TMD Friction provides best-practice braking tips this winter

The car's braking system consists of many components, and most of them are completely exposed

The car's braking system consists of many components, and most of them are completely exposed, which makes them susceptible to all kinds of pollution, road grit and moisture, and in the winter, to slush and snow. This applies to brake pipes and rubber hoses, calipers, ABS rings as well as brake discs and pads. It is therefore important that technicians have access to the highest quality parts and the technical know-how on best-practice braking tips.

Here, Scott Irwin MIMI, Head of Technical Training at TMD Friction explains the impact that winter conditions can have on the proper functioning of the braking system, providing the most relevant advice and support to take best care of it.

Particular attention should be paid to vehicle brake pipes and hoses, both rigid and flexible. Under the influence of slush and snow, old brake fluid with a lot of moisture in the system can be a harmful influence on these parts, as they can start to corrode from inside or outside.

To verify a brake hose defect, technicians should carefully examine the hoses and their metal terminals for leaks, rust or mechanical damage. The hoses need to be in good technical condition, as they act as the carrier of the brake fluid and are therefore crucial for the proper functioning of the brake system.

The operational efficiency of the brake fluid itself can be checked using a special tester, such as TEX1000BFT from Textar, which allows the technician to determine the exact boiling point of the brake fluid.

Manufacturers recommend replacing it on average every two years or 60,000 km, whichever comes first. When replacing the brake fluid, we must remember that boiling point is not everything – for proper operation of all systems, such as ABS / ESP, it is not enough that the fluid does not ‘boil.’

It must have the right viscosity, which ensures sufficient fast pressure changes in the system. It is important to choose not only the DOT classification by number, but also the proper viscosity (e.g. DOT4, DOT4LV).

ABS plugs and rings are another element susceptible to adverse winter conditions. Some replacement plugs do not have factory seals, for example.

In this case, the most dangerous element is the moisture, which can cause corrosion of electrical connectors.

The problem of rust can also apply to calipers, brake pads and discs, which means in all places where moisture gets. The brake pads can corrode together with the guides, which will prevent their free movement during brake operation.

The winter period is conducive to these phenomena due to the increased humidity. For example, a characteristic rust coating may appear on the surface of the brake disc. If these are trace amounts, when braking, the driver will hear the characteristic sound of scraping, similar to that of grinding steel with coarse sandpaper.

After a few braking operations, rust will come off and the specific noise will stop. In extreme cases, after a long standstill, corrosion can permanently damage the structure of the disc, so it is important that the technician can access high-quality parts and the owner is advised to drive the car regularly.

On the rear axle, the most common fault is the corrosion of the handbrake cables, which, if not used too often, tends to corrode faster. If the cable has a broken shield, water will get inside it. This causes contamination and progressive corrosion of the cable, especially of its ends, which in conditions of negative temperature can lead to a blockage.

If the water in the cable shield freezes, it may not be possible to release the hand brake in the cold.

In order to avoid problems with the braking system during winter, first of all it is recommended to check regularly its condition and if necessary to replace individual elements with new ones.

From the point of view of the correct operation of the brakes, assembly and maintenance of the system is very important.

It should be remembered that the appropriate points should be protected against corrosion with a dedicated ceramic or synthetic grease, depending on the purpose, such as Textar’s Ceratec – Texcear01.

Winter is coming: 32 million Brits admit to making mistakes

More than a quarter of Brits admit to leaving the car-running unattended to de-ice screens

More than a quarter of Brits (28%) admit to leaving the car-running unattended to de-ice screens

Common mistake could lead to people facing a fine and potentially being unable to claim on their insurance if their vehicle is stolen

Almost half (45%) admit to driving with limited visibility

More than half (57%) wear inappropriate clothing / footwear such as gloves and wellies

As winter takes hold and temperatures start to drop, research by Aviva reveals the most common mistakes drivers could be making when it comes to getting behind the wheel this winter.

The research, which surveyed 2,000 Brits, reveals that more than a quarter (28%) are leaving their cars running to de-ice screens, with older generations most likely to take the risk. Over a third of those aged 75+ (41%) and those aged 65-74 (34%) leave their car on to de-ice screens , compared to 17% of 18-24 year-olds and 24% of 25-34 year-olds.

By doing so, Brits may be unwittingly putting themselves at risk with most car insurance policies excluding thefts of vehicles while the engine is still running. This is also an offence under Section 42 of the Road Traffic Act 1988 which states that drivers cannot leave vehicles running and unattended while on a public highway, otherwise known as ‘quitting’.

When looking at visibility, the research reveals that almost half (45%) of Brits have driven without making sure that their screens and mirrors were properly clear. By doing so, motorists could also be risking a fine under Section 229 of the Highway Code, which states that all drivers ‘must be able to see, so clear all snow and ice from all windows’.

Other driving habits include leaving the car unlocked to quickly pop into somewhere (13%), pouring boiling water over a car windscreen to de-ice it (11%) as well as wearing inappropriate footwear such as heels (9%) or wellies/snowboots (7%). Those driving whilst wearing inappropriate clothing and footwear could also risk a fine under Rule 97 of the Highway code which states that you should ensure: ‘clothing and footwear do not prevent you using the controls in the correct manner’.

Martin Smith, Motor Claims Manager at Aviva, comments: “All drivers have a legal responsibility to ensure their vehicle is in a roadworthy condition and this means making sure all windscreens and mirrors are clear of any snow, leaves, debris, ice and dirt.

“While we all want to get to our next destination as quickly as possible, it pays to be safe, particularly as the risk of an accident typically increases during the winter months. Spending five or ten minutes to prepare your car means that not only are you more likely to avoid an accident, but also a hefty fine - which can be as much as £1,000 - points on your licence or even a driving ban in the worst case scenario.

“If you do leave the engine running to de-ice your car, be sure to remain in your vehicle at all times. Failing to do so means that you may not be able to make a claim on your insurance in the event that your vehicle is unfortunately stolen.”

Aviva’s five top tips for driving safely during tough weather conditions include:

1) Lights: During heavy snow or even heavy rain during winter days, using your headlights instead of daytime lights means that you are more visible to other drivers.

2) Gears: When setting out, starting off in second gear can help avoid wheel spin during ice and snow conditions. Drive in the highest gear possible, and at a very slow speed when on flat ground. When driving downhill, use third or fourth gear. When turning a corner use a lower gear. If your car is an automatic, consider using the manual override function. This will enable you to select the right gear to avoid braking as it can lead to skidding. In icy and snowy conditions, stopping distances can be increased tenfold so keep this in mind at all times.

3) Slow and steady: Accelerate and brake very gently and gradually, to avoid your car skidding. During wet and icy weather, the stopping distance significantly increases and so it’s important to leave as much room as you can between your car and the vehicle in front. Winter tyres may also help when it comes to gripping during tough weather conditions – just be aware that in some instances, you may need to let your insurer know if you are using them.

4) Be alert: Be particularly careful of roads in shaded areas, either by trees or buildings. It’s in these areas that black ice can often be found, as sunlight cannot reach them.

5) Never drive through flood water and take caution driving through fords or tides. Avoid driving through flood water where possible. It’s difficult to see how deep the water may be and you could end up becoming stranded or swept away. Just 30cm of fast-flowing water is enough to move a car3 During bad weather, fords and tides may be higher than usual and so if you’re ever in doubt, find an alternative route or wait for the tide to lower. It only takes a small amount of water to ruin an engine, so it pays to be cautious.

Navigating winter challenges: Starter motors and Alternators

As the winter chill sets in, vehicles face increased demands on their electrical systems

As the winter chill sets in, vehicles face increased demands on their electrical systems, leading to a higher rate of alternator failures. Autoelectro recognises the unique challenges posed by colder weather. Autoelectro’s Harnek Bhogal aims to shed light on the key factors influencing both alternator and starter motor performance, emphasising the unique quality and reliability of its remanufactured OE-spec units.

Alternators: Meeting winter’s electrical demands with premium quality

The main cause of the heightened rate of alternator failures in winter lies in the increased load placed on these crucial components. Drivers heavily rely on electrical systems during colder months, such as heaters, defrosters, headlights, and various climate control features. This increased electrical load puts additional strain on the alternator, as it must simultaneously power these systems while maintaining the battery’s charge.

Autoelectro’s remanufactured, OE-spec alternators stand out due to their quality, availability and ease of fitting. Harnek said: “Our units are manufactured with precision engineering, high-quality materials and adhere to the most stringent manufacturing standards. The components used in our alternators are durable and reliable, reducing the likelihood of failure, even in extreme cold temperatures.

“In contrast, ‘copy’ units often compromise on materials and quality control, making them more susceptible to malfunction in harsh environmental conditions. For motor factors, workshops and end-users, why take the risk?”

Efficiency is another crucial aspect where Autoelectro excels, according to Harnek. He continued: “Our alternators are designed for optimal proficiency, producing electrical power with minimal waste in the form of heat. This efficiency becomes particularly crucial in colder weather, where the engine may need to work harder to generate power. A better-quality alternator helps minimise strain on the engine, enhancing fuel efficiency, and reducing wear and tear on the vehicle’s electrical system.

Backed by a robust two-year warranty and enviable technical customer support, Autoelectro ensures peace of mind up-and-down the supply chain, especially in colder weather conditions where breakdowns can be inconvenient and potentially dangerous.

But what about starter motors?

Cold mornings pose a specific threat to starter motors too, with excessive cranking leading to an increased rate of burnouts. Autoelectro, with almost 40 years under its belt, knows the ‘normal’ reasons for its failures, including overheating, excessive cranking, and mechanical issues, such as being stuck in the mesh.

While the faults observed in returned cores remain consistent, the winter conditions exacerbate these issues. The strain on rotating electrics during winter mornings is unparalleled, making it crucial for vehicles to be equipped with reliable starter motors.

Conclusion

As winter conditions put additional stress on vehicles, Autoelectro stands as a beacon of reliability with OE-spec starter motors and alternators.

Harnek concluded: “Our commitment to quality, availability, and customer support ensures that workshops, motor factors and motorists can confidently navigate the challenges of winter, knowing they are backed by a renowned supplier.

For more information about Autoelectro, go to www.autoelectro.co.uk

Avoid the misery of a breakdown with simple car maintenance

MOTORISTS WITHOUT breakdown cover risk hefty bills if they suffer car trouble this winter

Plunging temperatures and snow predicted later this week

Motorists without cover risk big bills if they break down

Simple car checks help prevent most malfunctions

MOTORISTS WITHOUT breakdown cover risk hefty bills if they suffer car trouble this winter, according to road safety and breakdown specialist GEM Motoring Assist.

With early warnings of plunging temperatures and snow for many parts of the country in coming days, GEM is urging drivers to plan journeys, check vehicles and ensure they have breakdown cover in place.

Giving some attention now to batteries, tyres, antifreeze, wipers, lights and other vehicle essentials is the best way of ensuring reliability – not just for the cold weather predicted this week, but for the entire winter.

It’s also a key step towards making journeys safer, as it removes the risks that go with being stranded in a broken-down car, says GEM.

GEM road safety adviser James Luckhurst said: “No one wants their car to break down on a chilly morning... or at any other time. At best it will bring inconvenience and delay, but since we don’t choose the location of a breakdown, there can also be significant risks involved for you, your passengers and other road users.

“Prevention is always better than cure, so by attending to a few basic maintenance needs, you can greatly reduce the risk of a breakdown in the coming months.

“Additionally, a breakdown recovery policy offers you peace of mind if something does go wrong, as you won’t face an unexpected bill of several hundred pounds recovery and repair.”

Here are GEM’s five simple steps for reducing the chance of a breakdown or malfunction this winter:

1 Get the battery and charging system checked to ensure best performance. Cold weather puts a lot of strain on tired batteries, so consider replacing yours now to avoid the inconvenience of a breakdown.

If your battery seems to be turning your engine over more slowly than usual, get it checked straight away, including all connections. Similarly, if the red battery warning symbol illuminates on the dashboard, do get the battery checked.

2 Ensure your car’s cooling system has the correct levels of anti-freeze, which is vital to prevent the water in your engine’s cooling system from freezing.

3 Make sure all the lights on your car are working properly. Clean them regularly to ensure they are free of dirt, so that you can see, and others can see you.

4 Check tyre tread depth and pressure weekly through the winter. Good tyres will ensure the safety systems on your car are as effective as possible.

5 Check your windscreen wipers, front and rear. Make sure they are working properly and top up your screenwash regularly using cold weather washer fluid.

Are your customers prepared for winter?

It’s not just batteries – battery care

Rain, wind and generally, miserable weather is usually a given in the UK, but it’s common for the vast majority of drivers to be unprepared for the winter months.

As the clocks have gone back one hour and the evenings are darker quicker, it allows factors and workshops the opportunity to upsell winter products that customers may not have thought about.

There is usually a focus on the three B’s around the time; bulbs, blades and batteries, but what about everything else drivers may need in winter? Yes, the three B’s should be a focus, but they shouldn’t be the only product groups to sell because there are other aspects to consider when selling a battery for instance, such as a jump starter or charger to prolong its life in the future.

It’s not just batteries – battery care

Batteries can be negatively impacted by the cold weather, as when the temperature drops to freezing, a battery can lose up to 35% of its power, which is why it’s important for drivers to keep an eye on their batteries over winter and ensure they have the best tools to prevent the battery from failing.

For instance, Ring’s range of smart chargers can be left connected to a car battery without overcharging. The intelligent charger will know when a battery is fully charged and will switch to a float mode, so will only add charge again as the battery naturally discharges.

However, if the battery has been allowed to go completely flat, Ring’s compact lithium jump starters, the RPPL200 and RPPL300, are ideal. They will jump start the vehicle quickly, but are so small, they can be stored them in the vehicle, ready to use if needed again.

Got to pump it up – tyre inflators

Another important element for drivers to keep an eye on, not just during winter but all-year round, is tyres. The correct tyre pressure is incredibly important, especially in winter when road conditions are more treacherous, so should be checked regularly. To assist, Ring has a range of gauges for quick pressure checks, but if they need to be inflated, it also has a variety of tyre inflators to suit every driver’s need.

One that is incredibly popular and selling well is the new RTC4000, which is rechargeable, cordless and compact, so can be stored away until needed. It also has a memory function, so the user can save different tyre pressures and activate them easily from the home screen, and has an auto-stop feature, so there’s no risk of over inflating the tyre. The RTC4000 is easily chargeable via a USB Type C cable or 12V DC cable and is quick to inflate a tyre, even from flat, making this product an easy sell for retailers and reassures drivers if they go back to their vehicle and the tyre is flat, there’s an easy solution in their glovebox.

See the light – worklamps

It’s not just technicians that need worklamps, they can also be sold to drivers as a more reliable and powerful option to torches. It goes without saying that every driver should have a light source handy in their vehicle in case of a breakdown, especially in winter as it’s darker earlier, and it’s likely to happen in the dark. So, why not sell drivers a worklamp that can quickly charge, is versatile and provides incredible light output?

Ring’s range of fast charging worklamps includes the MAGflex Pro Fast Charge LED Inspection Lamp (RIL4200/REIL4200), which can go from 0-100% battery in just one hour. For a slim version of this, there’s the MAGflex Slim Fast Charge LED Inspection Lamp (RIL4300/REIL4300), with the same quick recharging time for a more compact option. Both would be suitable in the case of a breakdown and would add extra reassurance to drivers.

Melett urges technicians to think ‘turbo’ this winter

Melett is urging technicians to stay on top of turbo maintenance this winter

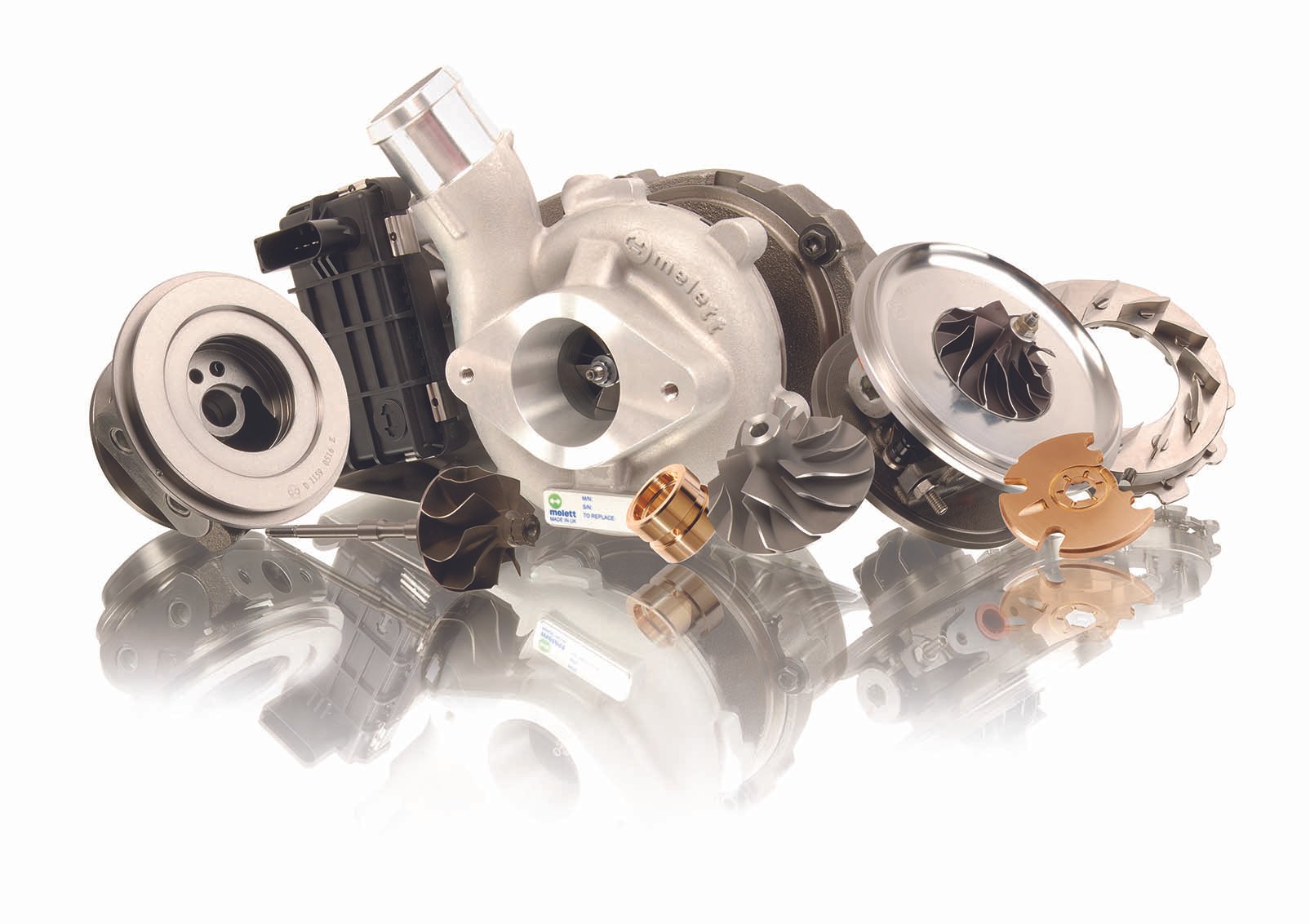

The trusted aftermarket brand for precision engineered turbochargers and parts, Melett, is urging technicians to stay on top of turbo maintenance this winter and has offered best practice tips to help customers prolong the life of their turbo, as temperatures plummet.

Lubrication is a key element to ensuring a turbocharger is doing its job correctly. Therefore, it is essential to check that a vehicle’s oil is the correct grade. When fitting a replacement turbo, it is important that the oil system has been primed and is in full working order. If this is not the case, it can lead to premature failure, says Melett.

Many turbo-related issues are simply down to neglect, and with more than a third of drivers expected to skip servicing their vehicle in a poll[1] taken in 2022, Melett is advising technicians to not only encourage regular servicing, but also to ensure the vehicle’s oil and oil filter is checked and replaced to protect the turbo from damage cause by contamination.

Another top tip for motorists is to adapt their driving habits during the colder weather, especially if the vehicle has not been run for long periods. Simple changes such as waiting a few minutes before driving at high revs to allow the engine to warm and oil to flow through the turbocharger. This prevents damage to components within the turbocharger.

By avoiding revving the engine, unnecessary stress on the turbo is avoided.

For more turbo tips and helpful video resources, please visit www.melett.com/technical

Lighting the way this winter

OSRAM, reminds workshops and factors to focus on bulb sales this winter

Leading lighting specialist, OSRAM, reminds workshops and factors to focus on bulb sales this winter, especially as the component is more likely to fail in colder temperatures.

With more than 110 years in the automotive sector, renowned lighting specialist, OSRAM, highlights why bulbs are more likely to fail in winter and why factors and workshops should be informing their customers of these facts, so preempting bulb failure and improving their bulb sales.

It’s a focus every year as the clocks go back, that factors and workshops should concentrate on their bulb sales and ensure their customers have the best light for the darker nights ahead.

Naturally drivers will notice if their bulbs are performing poorly, as they use them more over winter months, but factors and workshops should be actively encouraging drivers to consider their bulbs while they’re still working before they potentially break.

One of the main reasons for bulb failure in the winter months is due to the tungsten filament, which is a part of every halogen bulb and what generates the light when a current passes through it, as cold weather can cause it to contract, which can lead to it breaking.

Factors and workshops should also lean on the fact that because it’s getting darker earlier, drivers will want the best light source to see the road ahead, and should upsell better and whiter bulbs, so drivers can comfortably see everything on the road and have maximum visibility. OSRAM’s NIGHT BREAKER 200 is its brightest halogen bulb, with up to 200% more light on the road and up to 150 metre long beam. This product is one of the bestselling bulbs in OSRAM’s upgrade portfolio and widely regarded in the industry, especially as it was recently recognised in Auto Express’s 2023 Product Awards, and so would be an easy upsell for factors and workshops.

OSRAM’s Campaign & Communications Professional, Kristin Tränka, said: “We’re urging factors and workshops to really focus on bulbs for the winter months, as this is when lighting is at its most important. To be able to see the road clearly is vital for safety, so choosing bulbs shouldn’t be decided on price, but on quality and light distribution. As OSRAM is an original equipment manufacturer, we can guarantee to supply premium quality bulbs that have a long lifespan.”

For more information on the full OSRAM range visit: www.osram.co.uk/am

Unlocking profit opportunities in winter

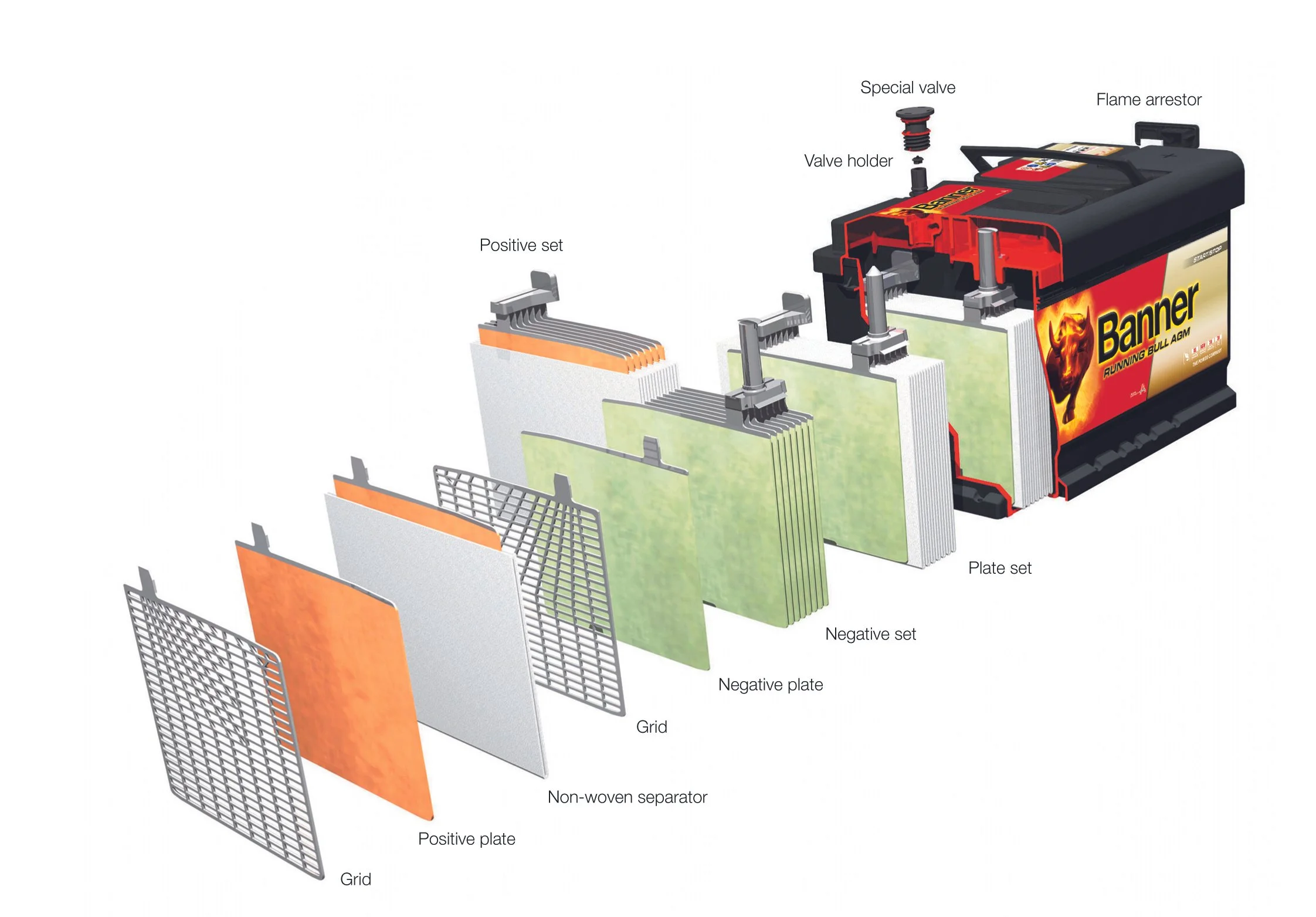

Russell Shea explores the rational reasons behind battery failure and replacing it with a premium battery is vital

In this final collaboration in the three-article series, Banner Business Development Manager, Russell Shea, explores the rational reasons behind battery failure and replacing it with a premium battery is vital, particular as temperatures plummet. This also represents opportunities for independent workshops and motor factors:

As automotive professionals serving the automotive aftermarket, we know this time of year marks the start of more and more panicky customers telling you that their car won’t start! While we know more batteries fail this time of year, do you know why? Do you also know how these failures can create profit opportunities and bolster your customer service?

The causes of battery failure:

Wear and tear: Battery wear and tear is a natural occurrence over time. Each cycle reduces a battery’s ability to supply current (CCA). Even in a discharged state, a battery in good condition can supply the specified levels of CCA when fully charged; however, a battery in poor condition will struggle to do so while still indicating a fully charged state.

Blowing hot and cold: Weather conditions play a significant role in battery performance. Cold weather affects battery plate aging and deterioration, reduces chemical reaction speeds, and increases starter motor power requirements. Charging system efficiency is also reduced. In contrast, hot ambient and under-bonnet temperatures accelerate battery aging, plate corrosion, self-discharge rates, and electrolyte use.

Plate sulphation: A natural element of battery discharge, this process coats the battery’s plates in lead sulphate when it reaches 12.4V or below. Battery discharge leads to the accumulation of lead sulphate on the plates. If a battery is not quickly recharged, these deposits can crystallise and harden, reducing battery performance. Poor stock control, recharge procedures, and undercharging conditions contribute to plate sulphation.

Acid stratification and deep cycling: Acid stratification occurs when acid in the electrolyte solution concentrates at the bottom of battery cells. This is more common in cold months and results from undercharging and short driving periods. Deep discharging and rapid recharging, as seen in taxis and delivery vans, can lead to rapid performance loss and premature failure.

Overcharging and undercharging: Overcharging is caused by a malfunctioning charging system, leading to battery overheating and electrolyte evaporation. Undercharging, common in vehicles used for short journeys, results in slow plate sulphation, particularly when alternator voltage is low, the drive belt is loose, or cables exhibit high resistance.

Short circuits, dead cells and internal breaks: Short circuits and dead cells are typical within the first year of battery service. Short circuits can be identified through lower specific gravity (SG) and boiling during discharge tests. Internal breaks are detected by good SG readings but no open circuit voltage reading.

Does product quality matter?

Product quality is paramount when it comes to car batteries! If the battery is the heart of a vehicle, would you settle for anything less than the best? Premium OE brand batteries, like that from Banner, are known for their quality and durability.

When compared to private label products of the same size and specifications, premium batteries often stand out in terms of weight, indicating a higher lead content. Manufacturers can cut costs by reducing materials used in battery construction, resulting in smaller, thinner, and fewer plates, but this cost-cutting approach compromises the battery's reliability, specification, performance, and overall lifespan.

In such batteries, power delivery is often achieved by increasing the acid concentration in the electrolyte. Unfortunately, this has a direct and detrimental impact on performance and longevity. A battery’s life cycle, divided into three phases – formatting, peak and decline – is compromised when plate numbers and lead content are reduced, and acid strength is increased.

Conclusion

Understanding the causes of car battery failures is essential for automotive aftermarket professionals. The winter season poses unique challenges to battery health.

By being proactive and addressing these issues, reiterating the importance of using a premium battery, we can help motorists keep their wheels turning and enjoy a reliable and problem-free driving experience. This proactive approach not only benefits the customers but also creates profit opportunities for both technicians and motor factors.

PartsinMotion encourages motorists to complete wiper check

Wiper blades will get a good workout during the colder months

With all the extra spray from not just rain but also ice and snow, wiper blades will get a good workout during the colder months. To maintain a good level of visibility at all times PartsInMotion.co.uk says motorists should check their wiper blades for signs of wear and tear.

Matt Gates, managing director at PartsInMotion.co.uk comments: “Drivers should be giving their wiper blades a regular clean throughout the year to give them the best chance of clearing the windscreen and ensuring they are in the best condition at all times.”

The arrival of autumn brings with it the rainy and snowy seasons. As windscreen wipers are one of the most hard-working parts of a vehicle, but the least durable thanks to the constant attack from weather conditions, bugs, pollen and leaves, the recommendation is to replace them every 12 months.

Gates adds: “The key signs wiper blades need replacing are smears and streaks on the glass, which are usually caused by cracked edges in the wiper blades’ rubber structure. They could also start squeaking and skipping as the wiper moves across the windscreen due to hardened rubber as the blade ages.”

PartsInMotion.co.uk offers fast delivery on leading automotive parts brands, including wiper blades from Bosch, Blue Print, Borg & Beck and Quinton Hazell.

If you’re in need of any parts or products to help keep your vehicle in good health, simply enter your vehicle registration at PartsInMotion.co.uk or speak to one of PartsInMotion.co.uk ‘s product experts to find out more.

Falken expands cold weather tyre offering

Falken is expanding its range of winter tyres with the EUROWINTER HS02 and HS02 PRO product lines

Falken EUROWINTER HS02 now available in 45 sizes

Falken EUROWINTER HS02 PRO now available in 74 sizes

Together with recently launched EUROALL SEASON AS220 PRO, Falken offers a comprehensive range for the winter season

Falken is expanding its range of winter tyres with the EUROWINTER HS02 and HS02 PRO product lines now available in a choice of 45 and 74 sizes respectively. In addition to adding numerous sizes to its range of winter tyres, Falken is also offering a new all-season tyre, the Falken EUROALL SEASON AS220 PRO. Designed to perform all year round and available in Europe since mid-September, the EUROALL SEASON AS220 PRO is aimed specifically at performance-oriented vehicles.

The cold time of the year brings a variety of challenges for car journeys. As the only connection between the vehicle and the road, the tyre plays a crucial role. In this respect, good grip on wet roads and balance between the grip in snowy, wet and dry conditions are particularly important. Thanks to state-of-the-art development and production processes, both Falken cold weather patterns feature an outstanding cold weather performance and also impress due their higher rates of fuel efficiency and durability.

The Falken EUROWINTER HS02 and HS02 PRO cold weather product lines feature a dynamic sidewall design, a lower weight and numerous innovative technical features. The excellent aquaplaning properties of the two Falken tyres are also no coincidence: in the case of the Falken EUROWINTER HS01, a symmetrical and directional V-profile increases water drainage, while an asymmetrical three-zone tread on the HS02 PRO is responsible for clearing water in wet conditions. Due to this new tread design and the higher speed ratings, the Falken EUROWINTER HS02 PRO is aimed squarely at the performance-oriented drivers of passenger cars and SUVs, a new sector for Falken.

The same applies to the Falken EUROALL SEASON AS220 PRO, with the design of the tyre optimised to meet the requirements of high-performance vehicles in both summer and winter seasons. The improved contour prevents a deformation of the tread and compensates for centrifugal forces at high speeds, resulting in more consistent contact with the road. This ensures improved stability and responsiveness whilst steering and braking, even at higher speeds.

Launched in 2022, the Falken EUROWINTER HS02 is now available in 45 sizes from 14 to 20 inches in the 45 to 70 series. Depending on its size, the tyre has the speed index T/H or V and is approved for speeds of up to 240 km/h. The Falken EUROWINTER HS02 PRO, which comes with a speed index of H/V/W, depending on the size, has a higher rating and allows for speeds of up to 270 km/h. This tyre is available in 74 sizes from 16 to 21 inches in the popular 35 to 70 series. The newcomer to the all-season segment, the Falken EUROALL SEASON AS220 PRO, is available in 45 dimensions from 17 – 21 inches, across the 35 – 65 series and is also rated for speeds of up to 270 km/h.

ZF Aftermarket gives five tips for a professional winter checkup

ZF Aftermarket gives five tips for a professional winter checkup

Cars need to be made fit for the coming winter season – even if they have all-season tyres

For a safer drive, customers need their vehicle to be in good technical condition

ZF Aftermarket offers an extensive spare parts portfolio for a professional winter checkup

Many vehicle owners only think about ‘winter-proofing’ their cars when the first snowflakes start to fall. Automotive workshops should see the next few months as an opportunity to plan ahead and get their customers into the workshop for a check – including users of all-season tyres, says ZF Aftermarket.

For a safer drive, when customers come in for a winter checkup, the focus should not be on changing the wheels alone, but on checking the entire vehicle. The right spare parts for the chassis system – up to and including air suspension – are available from ZF Aftermarket with its Lemförder, Sachs, TRW, and Wabco brands.

The chassis systems of many passenger cars worked harder than normal during the summer season. Holiday trips and trailer operation were added to the usual usage for many drivers and put immense stress on the vehicle, particularly on its suspension system. And now the winter season is just around the corner, bringing with it salt spray and debris from the roads, and workshops need to prepare customers for the cold, wet conditions with snow and ice.

Therefore, ZF Aftermarket recommends that automotive workshops take advantage of the weeks before winter sets in to invite their customers for a winter check. For users of seasonal tyres, the need is self-evident due to the wheel change, but drivers of all-season tyres should also receive this invitation.

Despite the current difficult economic situation in many households, the willingness to keep one's own car safe and fit for purpose remains high. In a recent survey by the German expert organisation, KÜS, 100 percent of respondents said that it was important to them that their car was in good technical condition. Eighty-eight percent have damage repaired as soon as possible, and 75 percent think proactive contact by their workshop is good or even very good.

To make the winter check a success for both the customer and the workshop, the experts at ZF Aftermarket offer the following five tips:

1. Optimise workshop planning: When a wheel change is necessary, it should not be done at a "pit-stop" pace. There must be time for a complete vehicle inspection to uncover all defects.

2. Ensure transparency: If the customer is not present during the vehicle check, the technician should document the vehicle components in need of repair by photo or video.

3. Expand damage diagnosis: When changing wheels, not only check the condition of the brakes, but all of the suspension components as well. Coil springs damaged by stone chips, for example, can corrode under the influence of salt in winter and break later. Even minimally leaking air springs can cause expensive consequential damage.

4. Carry out a battery test: This should be part of every winter check. Otherwise, there is a high risk that the customer will be stranded on the first cold days – which is particularly annoying shortly after a workshop visit.

5. Market and upsell accessories: When making an appointment (online), customers should be given the option of ordering seasonal accessory packages – for example, care products, snow chains, rubber floor mats or similar.

With its Lemförder, Sachs, TRW and Wabco brands, ZF Aftermarket offers a full parts and service solution for the entire chassis system. New to the range is the Wabco brand with its range of air suspension compressors for many passenger car models. This is proven original equipment technology that has already been installed in millions of vehicles.

The TRW range includes brake discs, brake pads and spare parts for drum brakes, brake fluid, hoses and all other brake service components. Under the Sachs brand, ZF Aftermarket supplies all types of shock absorbers, and air springs. Lemförder is the specialist in steering and chassis technology, with control arms, coupling rods, wheel joints, and much more.